Associate Professor Jennifer Loy has a PhD in Industrial Design and background in design for mass production. Her research interests focus on digital fabrication, in particular 3D printing and its impact on design. Jennifer is Program Leader of Industrial Design and 3D Design Digital Media at Griffith University and teaches 3D printing into both programs. Jennifer’s research collaborations are across disciplines, applying design thinking and 3D printing as a transformative technology in diverse situations, from humanitarian logistics and medical modelling, to digital fashion design and commercial product design. She is a speaker on creative design for 3D printing around the world.

Transcript:

The objects that we see around us look the way they are because of the way they’re manufactured.

If we want to make an object, we build a mold, we put material into it, and then we pull that mold apart. But we have to think of the pathways of the mold and that restricts what we can actually make.

Otherwise we can get a block of material and we can cut into. But we still have to think about the tool, and also, it wastes a lot of material.

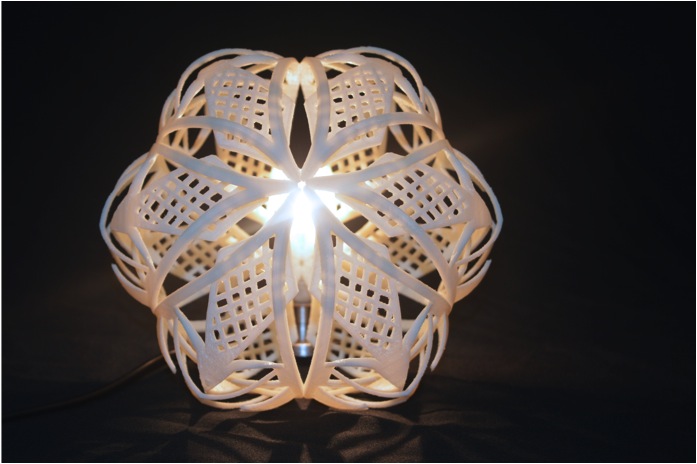

3D printing is different. In 3D printing, we work in the virtual environment. We build our model, we split it into layers on the computer, and then we print it, layer by layer til it grows into its shape.

This means that we can use complex geometries that just weren’t possible before, and there’s no waste. And also, because there’s not cost of the mold, it means we can customise each print.

What would you like to see 3D printed?”

Know More in Sixty Seconds is a place dedicated to finding and sharing amazing knowledge in tasty little video bites. This is just one of them. Discover more

It is very impressive, if you search for printing online, most of the topics these days, are all about the 3D printers and tutorials on how to make them work properly.