A chemical explosion has disbursed a toxin across inner city suburbs. Hundreds of people are presenting at hospital even though only a fraction have come into contact with the poison. Hysteria has set in, people who are not even close to the toxins present as if they have been poisoned. Imagine the advantage to hospital staff if a device no bigger than a mobile phone could detect who has in fact had a toxic response.

Lab-on-a-chip represents a suit of technologies that in the future will be able to do just that and much more. Over the coming decades the technology is poised to revolutionise health-care, environmental monitoring and a host of other industries in ways we are yet to imagine.

This article was first published in Impact @ Griffith Sciences magazine. Click here for more details

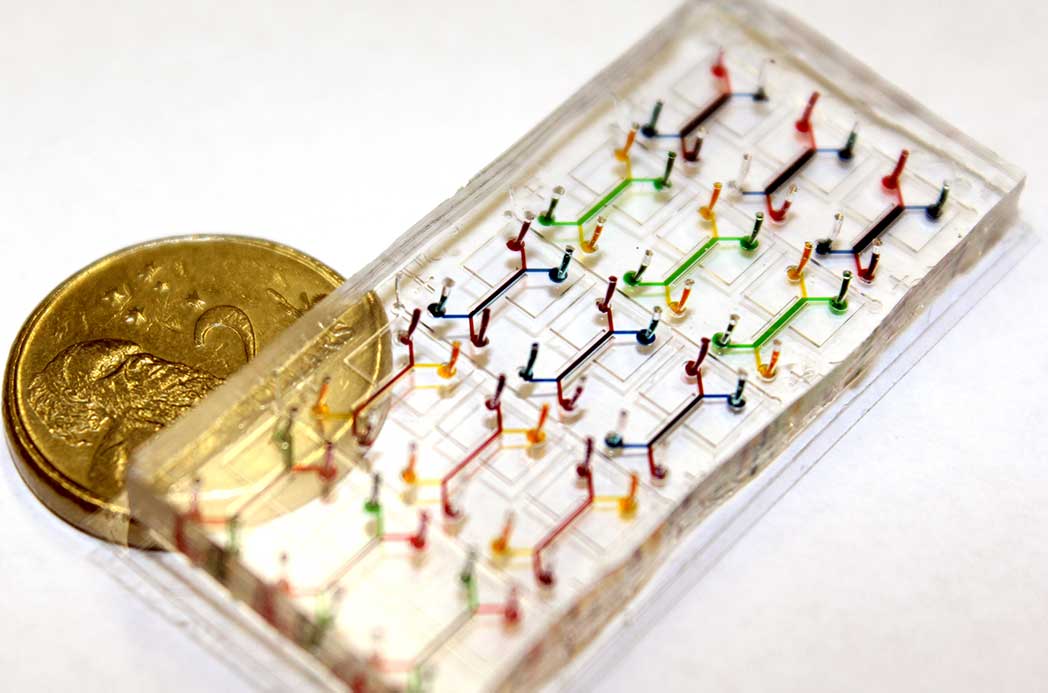

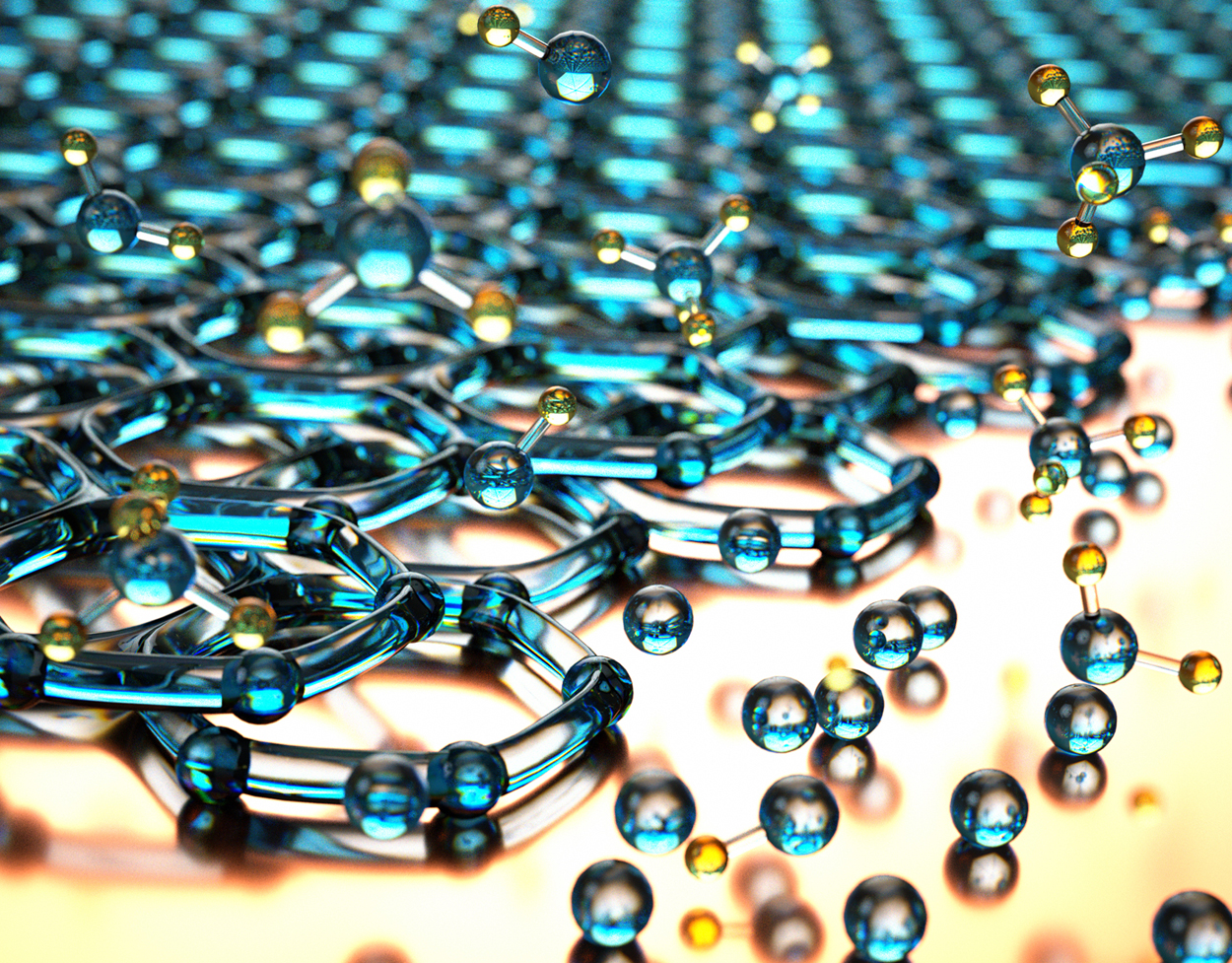

As the name implies lab-on-a-chip shrinks a host of different protocols and processes down to the micro-scale. Experiments that currently take days to perform and utilise multiple laboratories could take place in a fraction of the time and cost. Tiny pumps, mixers, valves, flow sensors, heating elements, reaction chambers and other micro-machined components are plumbed together with capillary connection, channels the diameter of a human hair, to perform experiments on mere pico-litres of reagents. An average raindrop contains hundreds of thousand pico-litres.

Professor Nam-Trung Nguyen, Director of the Queensland Nano and Microtechnology Centre, believes what we have seen so far in this space is really only a glimpse at the possibilities lab on a chip technology could deliver.

“At present many of the chips being produced have a small range of capability and are mostly for research purpose or serve as tools to help other research areas such as rapid screening for drug-like substances,” says Professor Nguyen.

“As the technology improves, the devices will get smaller and incorporate more features. Lab-on-a-chip devices could be adopted in everything from assisting triage in hospitals to scan for patients with broad range diagnostic tool to detecting pollutants entering ecosystems in minutes rather than hours.”

Currently Professor Nguyen is working to build all the different cells found in a human lung, onto a chip the size of a credit card. Even more amazing is that the chip can mimic in-vivo physical condition such as the stretching of the cells during the breathing process.

“We are working to create on organ on a chip to give a quick and relatively cheap assay for scanning how new drugs interact with cells under a similar conditions as inside the body,” explains Professor Nguyen.

“We’ve even incorporated tiny optical components such as lenses to act as a microscope, giving traditional sensors enough light to read the results of the micro- experiments.”

The path to market and acceptance of these technologies into the wider community does not rely solely on technological wizardry. Uptake, adaption and market penetration are all factors that drive how a technology makes its way from the research bench to everyday life.

“We are showing a proof of concept. We show that the technology works and that the manufacturing process can be up scaled. “